Carbstone Innovation

Carbstone Innovation is a patented technology with which we can develop high-quality materials by adding CO2 to Carbinox®. The technology was developed in collaboration with VITO and the Walloon CTP.

Thanks to carbonation technology, materials can be developed in all kinds of forms: from floor tiles and roofing tiles to clinkers, building blocks and even briquettes for the steel industry.

In so doing, CO2 and Carbinox® combine to act as a binder, instead of cement. That makes these products extremely long-lasting and environmentally-friendly, since they ensure a unique, permanent storage of a substantial quantity of CO2.

History

The team behind Carbstone Innovation NV has a background in processing and transporting materials from stone quarries for dyke improvements, road works and public procurement contracts. Since 1996, TRC and Recmix Belgium, the parent companies of Carbstone Innovation NV have been transporting and processing slag from the stainless steel factories in Genk and Charleroi. Slag is a by-product arising during the manufacture of steel and primarily consists of anorganic minerals.

As soon as slag is broken, it quickly becomes obvious that it contains a considerable portion of recyclable metal. Recmix Belgium developed the necessary technology to recover this metal fraction and it is still doing this today. The remaining anorganic fraction is primarily used in road construction (asphalt) and in concrete applications.

In 2004, Recmix discovered that the finest residual fractions of slag harden due to the limited concentration of CO2 in the atmosphere. This process is based on the carbonation of the CaO and MgO contents that is present in the slag in large quantities. Research and development in collaboration with the VITO resulted in a patented process to accelerate this natural process to make high value construction materials from these fine residual fractions, and thereby to offer an environmentally friendly solution for the slag as well as for CO2. Carbstone Innovation NV was founded based on this technology in 2009 with the aim of bundling together the knowledge and skills of Recmix Belgium BVBA and VITO NV in the field of the carbonation of slags.

Today, Carbstone Innovation NV is a full fledged subsidiary of Recmix Belgium BVBA and represents a series of technologies aimed at processing secondary raw materials in an environmentally friendly manner, with the core competence being the carbonation of (metal) slags. We want to further develop, expand, and implement these technologies not only for ourselves, but also for third parties, and thereby to offer society a cost-efficient and environmentally friendly solution for the CO2.

About us

Carbstone Innovation NV was set up with the objective of developing, promoting and commercially exploiting the technology relating to carbonation, and thereby to make a substantial difference to society with regard to waste processing. In principle, we strive to create new raw materials from products that used to be labelled as waste in the past, and thereby reuse the same to the maximum extent. Slag from the steel industry has constituted a major source of raw materials for many decades so far, and is not being fully utilised, even now. Carbon dioxide - greenhouse gas - has been the subject of many studies since it is believed to cause the global warming of the atmosphere.

Using the Carbstone process, these two products, until recently labelled as waste, can create a sustainable and innovative product that contributes to a greener society. Carbstone Innovation NV ensures the further development of the technology to achieve an increasingly better and more efficient processing of CO2 and slag into high value products. A wider investigation is also to be made for other raw materials that could possibly contribute to a greener economy. In this connection, we strongly emphasise the C2C - cradle to cradle – principle.

In order to achieve this aim, we also have to collaborate with all kinds of stakeholders, of course: partners, researchers, governments, but definitely local residents and the general public as well. We strive to carry on our operations with due regard to each of these groups.

Pilot plant

Under the impetus provided by the Walloon Marshall Plan and within the “Pôle Mecatech” (CARMAT project), Recoval Belgium BVBA (sister company of Carbstone Innovation NV) has been working since the summer of 2013 on the construction of a full-fledged pilot plant in which carbonation technology, as patented by Carbstone Innovation NV, will play a central role. Slag of various origins will be treated in this plant, located along the Sambre River in the Farciennes - Walloon Municipality (near Aperam Carinox). The functional objective of the plant is to use carbonation to manufacture high value construction products from two residual products, namely steel slag and CO2. In their untreated form, these two products are waste products and after undergoing our process, they can be reused as a raw material for all types of applications.

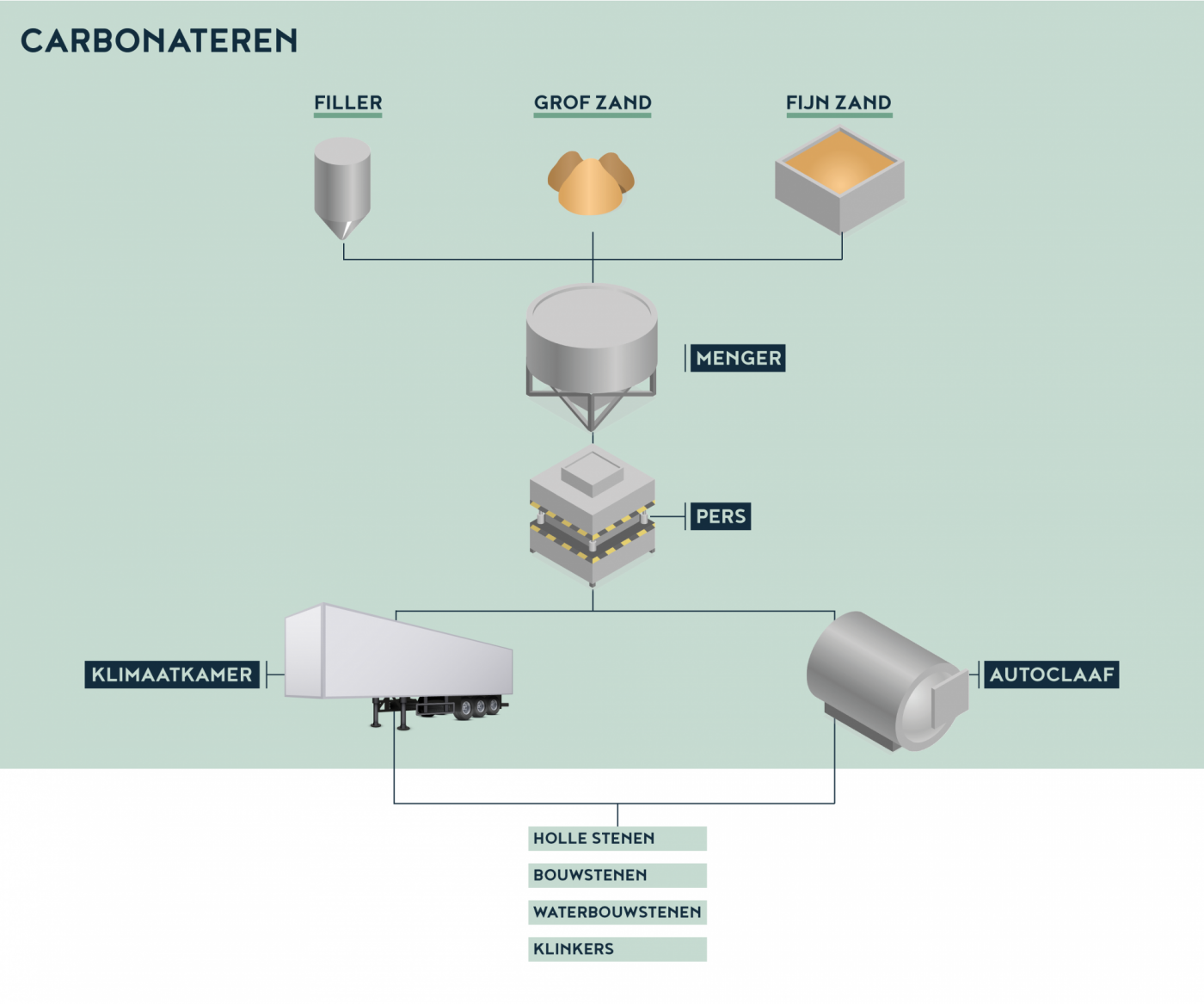

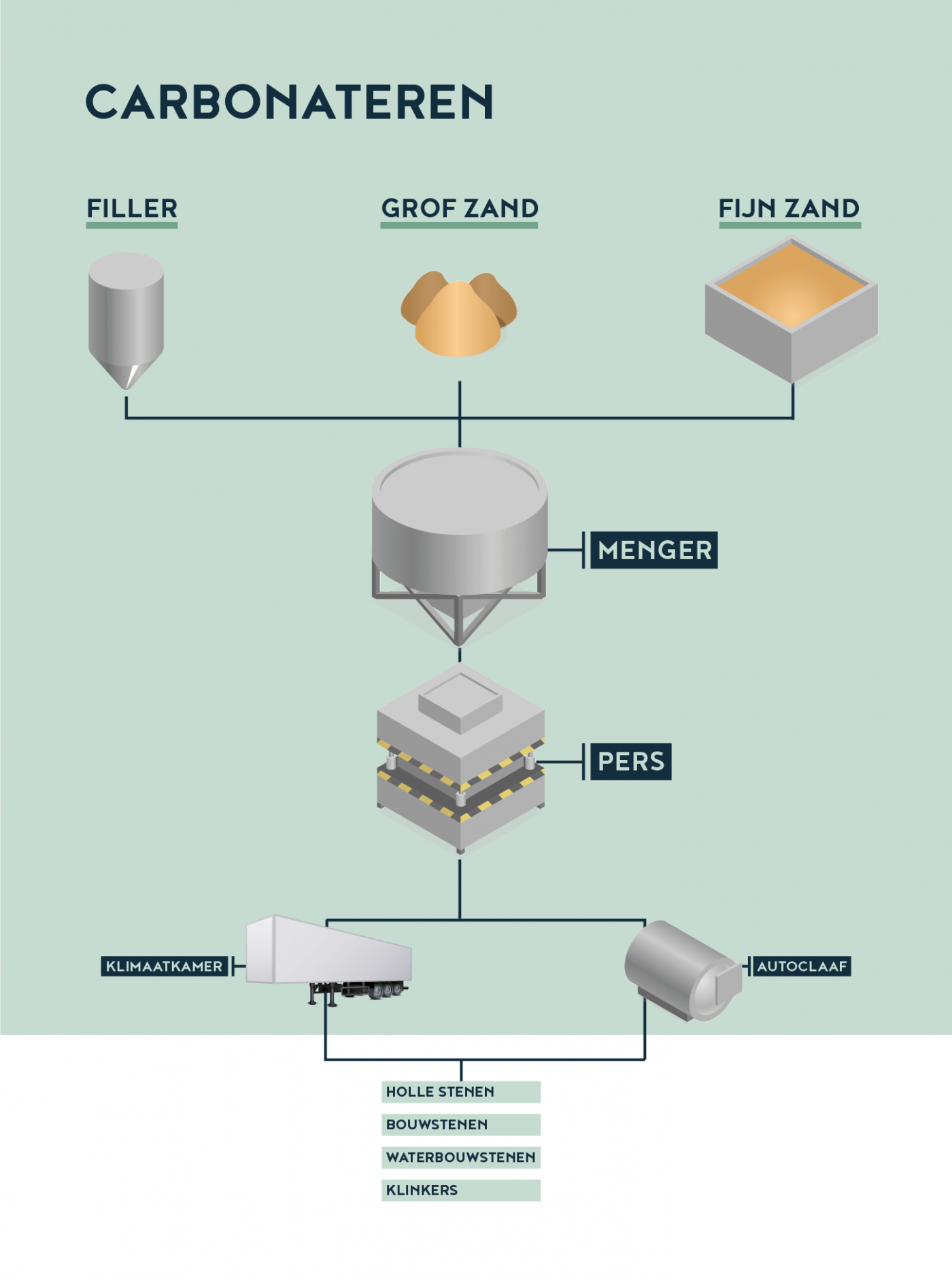

In order to provide sufficient raw material for the carbonation process, an innovative grinding mill has been integrated in the factory due to which we can process rough metal slag into a fine fraction (filler) suitable for carbonation on the one hand, and can recover the existing metal on the other. This method of working allows us to very precisely control the particle size and the moisture content of the raw material, and thereby to optimise the process. In the factory, two mixers mix the various raw materials (fillers and various slag sands) with a quantity of water. This water will be used to hydrate the existing CaO and to enable carbonation. The next step is shaping, which is done by a large press. This press can create a wide range of bricks, both hollow as well as solid. The carbonation itself is done in an autoclave under high pressure and temperature, which makes it possible to manufacture bricks with strengths exceeding 100 MPa. This opens the door to a wide range of applications, ranging from clinker to industrial construction blocks.

The aim of this plant is twofold: it will enable us and our clients to carry out research and development activities on an industrial scale. This will bridge the gap between the laboratory and the production plant, thereby making possible realistic cost estimates, process parameters and turnaround times. Secondly, it will be possible to use this plant on the request of clients and partners to efficiently convert specific tonnages of slag into building blocks. It is therefore a combination of a production and an R&D plant.

Applications

Tiles - Roof tiles - Clinkers - Boarding stones - Building blocks - Briquettes

In association with

Do you want to implement the carbonation technology in your company?

We like to join forces to make it a success specifically for your production process.